The spec says "provide electrical connections to mechanical equipment." But who provides the disconnect? The junction box? The flexible conduit?

Nobody priced it. Now it's a $15,000 argument.

Scope gaps are the "small" misses that cost disproportionate money—not because the item is expensive, but because discovering it triggers disputes, delays, and relationship damage.

Here's how to find them before they find you.

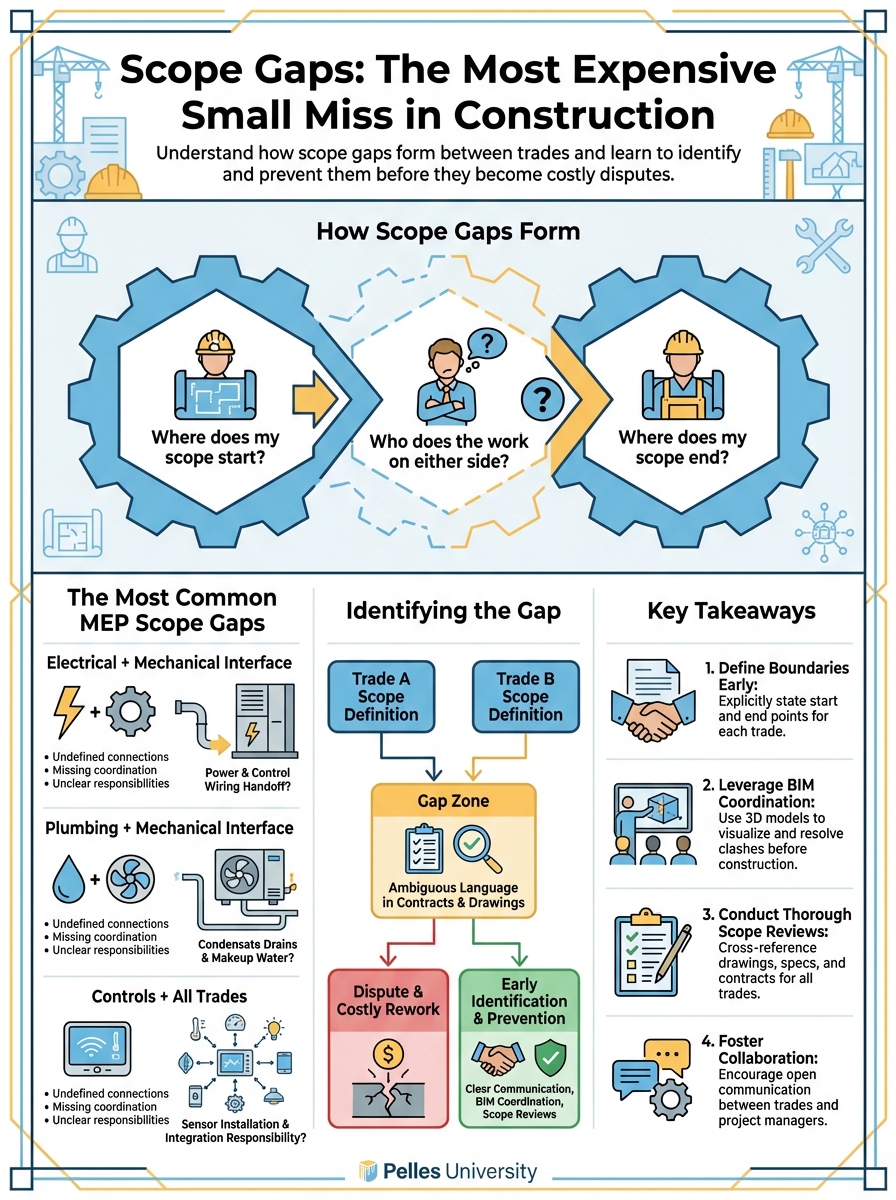

How Scope Gaps Form

Scope gaps appear at boundaries:

- Between trades – Electrical thinks mechanical handles it. Mechanical thinks electrical handles it.

- Between documents – Shown on drawings, not in specs. Or in specs, not on drawings.

- Between bid packages – GC scoped it to one trade in the estimate but not in the contract.

- Between phases – Phase 1 assumed Phase 2 would cover it.

The common thread: assumptions. Scope gaps live in the space between what people think they agreed to.

The Most Common MEP Scope Gaps

Electrical + Mechanical Interface

| Item | Often Assumed By | Actually By |

|---|---|---|

| Disconnects | Electrical | Varies—check specs |

| Final connections | Electrical | Varies—check specs |

| Motor starters | Either | Usually mechanical |

| VFDs | Either | Mechanical (usually) |

| Control wiring | Controls sub | Sometimes mechanical |

Example: Mechanical provided an RTU with factory-mounted disconnect. Electrical quoted based on field-provided disconnects. Neither realized the conflict until equipment arrived.

Plumbing + Mechanical Interface

| Item | Often Assumed By | Actually By |

|---|---|---|

| Condensate drains | Mechanical | To point of connection; plumbing beyond |

| Makeup water | Mechanical | Plumbing provides to equipment |

| Gas piping | Plumbing | Sometimes mechanical for specific equipment |

| Glycol systems | Either | Check spec carefully |

Controls + All Trades

| Item | Often Assumed By | Actually By |

|---|---|---|

| Field sensors | Controls | Often mechanical/electrical to furnish |

| Conduit and wire | Electrical | Sometimes controls |

| Integration | Controls | Building automation only; other systems separate |

| Programming | Controls | Often split—DDC vs. third-party systems |

Insulation

| Item | Assumed Location | Reality |

|---|---|---|

| Pipe insulation | Mechanical | May be separate division (Division 22 vs. 07) |

| Duct insulation | Mechanical | Same issue |

| Equipment insulation | Mechanical | Factory-applied or field-applied? |

How to Find Scope Gaps Early

Method 1: The Boundary Walk

For each system you're providing, ask:

- Where does my scope start?

- Where does my scope end?

- Who does the work on either side?

- Is that explicitly stated in my contract?

Method 2: The Specification Cross-Reference

When a spec section says "coordinate with" or "see Section XX," go read Section XX. Verify:

- Is that work in someone's scope?

- Does their scope include the interface?

Method 3: The Drawing Review

Look at:

- One-line diagrams (electrical)

- Piping and instrument diagrams (mechanical)

- Riser diagrams (plumbing)

Find every point where your system connects to another. Confirm that connection scope is assigned.

Method 4: The RFI Test

If you're not sure who provides something, neither is anyone else. Issue an RFI:

"Please clarify responsibility for [item]. Specification Section XX references [requirement], but scope assignment is not clear in Division XX or Division YY."

This forces a documented answer before you're standing in the field arguing.

Using AI to Identify Potential Gaps

Review these MEP specifications and identify potential scope gaps:

[Paste relevant spec sections]

For each gap identified:

1. Describe the item or work

2. Identify which trades might assume responsibility

3. Quote any conflicting or unclear language

4. Suggest an RFI to clarify

Focus on interfaces between:

- Mechanical and electrical

- Mechanical and plumbing

- Controls and all trades

- Insulation scope

- Testing and commissioning

Documenting Scope Boundaries

Once you've identified boundaries, document them:

In your inclusions: "Provide RTUs complete with factory-mounted disconnects."

In your exclusions: "Field-installed disconnects—by Electrical Contractor."

In your clarifications: "Electrical connections by others. Mechanical contractor provides junction box at unit. Final connection from junction box to building electrical system by Electrical Contractor."

When both trades document the same boundary consistently, there's no gap.

When You Find a Gap During Construction

If a scope gap appears in the field:

Step 1: Stop and Document

Don't do the work "to keep things moving." Take photos. Write it up.

Step 2: Notify the GC in Writing

"During installation, we identified that [item] is not included in our scope per Section [XX]. Please advise responsibility."

Step 3: Propose Solution (If Asked)

"We can perform this work on a time and material basis. Estimated cost: $X,XXX."

Step 4: Get Direction in Writing

Don't proceed on verbal instructions. Get a change directive or signed T&M ticket.

The Scope Gap Prevention Checklist

Before signing your subcontract:

Trade interfaces:

- Electrical connection scope defined

- Controls/BAS interface defined

- Insulation scope verified

- Commissioning support scope defined

Document alignment:

- Spec scope matches drawing scope

- Drawing details match schedules

- Exclusions list covers boundary items

Clarifications:

- Ambiguous items addressed in RFIs

- Responses incorporated in bid

What's Next

Scope gaps caught before contract are clarifications. Scope gaps caught during construction are change orders—or worse, disputes. The next step is building gap analysis into your standard bid review process so every estimator checks the same interfaces.

TL;DR

- Scope gaps form at boundaries—between trades, between documents, between phases

- Common gap zones: electrical connections, insulation, controls interfaces

- Walk the boundaries: where does your scope start and end? Who owns each side?

- If you're not sure who provides something, issue an RFI—get clarity before construction

- Document scope boundaries explicitly in inclusions, exclusions, and clarifications